Capabilities

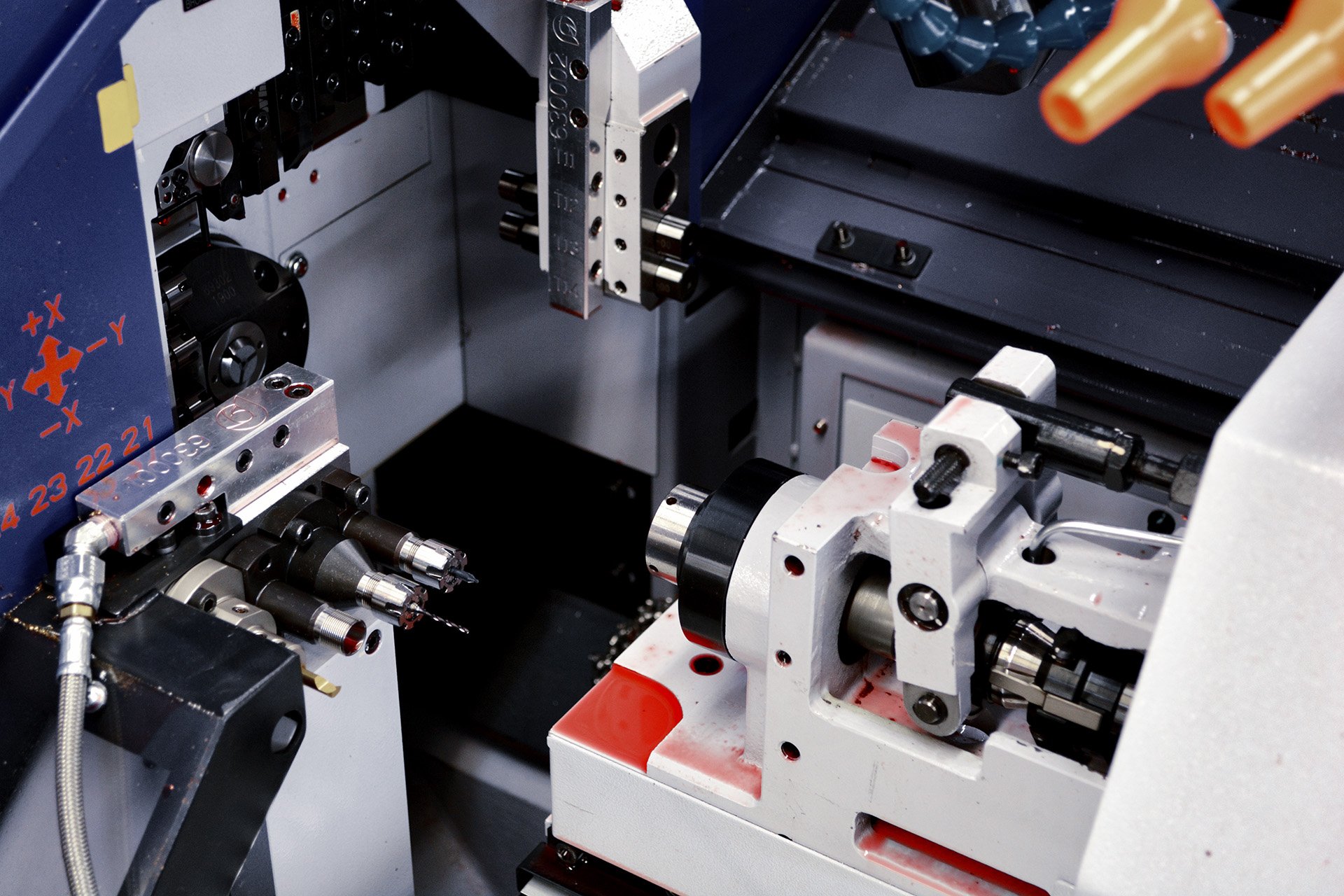

Maximum Readiness. Our 35,000 sq ft climate-controlled facility in Bensenville, Illinois is where we machine all metals and plastics. Our state-of-the-art CNC machines run in a lights-out environment, which enables us to operate a 24-hour nonstop production cycle for greater capacity, and shorter lead times.

We are located near O’Hare International Airport, where the Chicago area provides quick access to materials, tools, supplies, and outside processors.

Modern Manufacturing

Staying Ahead. We have extensive manufacturing capabilities that service various industries. LD Redmer stays ahead of what’s required by adding new machines, with the latest technology in advance of growth, so we can quickly respond to new opportunities and stay on the leading edge of manufacturing.

Assembly

Bar-Code Labeling

Cleaning

Grit Blasting

Milling (including 5-axis)

Packaging

Part Marking

Press-Fit Assembly

Prototyping

Screw-Thread-Insert

Assembly

Swiss Machining

Thread Rolling

Turning

Ultrasonic Cleaning

Vacuum-Table Milling

Welding

Assembly Bar-Code Labeling Cleaning Grit Blasting Milling (including 5-axis) Packaging Part Marking Press-Fit Assembly Prototyping Screw-Thread-Insert Assembly Swiss Machining Thread Rolling Turning Ultrasonic Cleaning Vacuum-Table Milling Welding

Complexity

Comfort in Complexity. We specialize in machining complex parts with attention to tight tolerance. Our capability utilizes the latest technology in multi-axis CNC lathes, including Swiss type and CNC mills, with 3- , 4- and 5-axis capability that supports the demands of machined parts requirements of most industries.

Any type. Any grade. We manufacture machined parts in most grades of metals and plastics, including hard-to-machine materials required by the aerospace industry.

Materials

Aluminum

Brass

Bronze

Copper

Engineered Plastic

Inconel

Nitronic Alloys

Steel

Stainless Steels

Titanium

Aluminum Brass Bronze Copper Engineered Plastic Inconel Nitronic Alloys Steel Stainless Steels Titanium

Outside Processing

A Network of Experts. LD Redmer employs an extensive network of outside processors in the Chicago area and elsewhere. We also comply with our customers’ approved processor lists including NADCAP-certified sources required by the aerospace industry.

LD Redmer offers parts complete to customer’s drawings and specifications and includes all outside processes.

Heat Treating

Chemical Filming

Passivation

Plating

Painting

Non-Destructive Examination

Heat Treating Chemical Filming Passivation Plating Painting Non-Destructive Examination

Machines

Tools of the Trade. Our state-of-the-art machines help us serve a broad spectrum of industries. They automatically load bar material from 1/8” to 3” in diameter. Parts up to 8” diameter are machined on chucking CNC lathes, and our CNC mills have a capacity of up to 29” X 24” X 24”.

Machines List

Machines in Lights Out Environment

Max Bar/Chuck Size

CNC Lathes with Twin Spindles, Twin Turrets with Magazine Bar Feeders

2” to 3” Bar/8” Chuck

CNC Lathes with Twin Spindles, Single Turrets with Magazine Bar Feeders

2.625” to 3” Bar/8” Chuck

Multi-Axis CNC Swiss Type Lathes with Twin Spindles and Magazine Bar Feeders

10 mm to 38 mm

CNC Lathes Gang Tool Type

1.0625”

CNC Mills

Axis X-Y-Z

CNC Horizontal Mills with Pallet Changer and Tombstone Fixtures

29”-24”-24”

5 Axis CNC Mills

39”-20”-12”

3 & 4 Axis CNC Vertical Mills with Indexers

30”-16”-12”

CNC Vertical Mills with Vacuum Table

28”-16”-16”

Quality Control Equipment

Microscopes

Mitutoyo

Leica

Cole Parmer

Hawkeye

Surftest Profilometers

Mitutoyo

Vision Systems

Vici MTL 300 EVO

Keyence IM 6225 & IM 7000

Ram Optical Star

Coordinate Measurement Machines

Hexagon Metrology PC-DMIS software

Brown & Sharpe PC-DMIS software

Digital Height Gages

Starrett

Brown & Sharpe

Force Tester

Mark-10 ESM303

Hardness Tester

Wilson

Laser Micrometers

Z-Mike M91 and M115

Digital Optical Comparators

Micro-Vu

CCP

Scherr-Tumico

Starlite GX150

Additional Capabilities

Thread Rolling Machines

Manual Lathes, Mills, Drill Presses

Hydraulic Presses

3D Prototype Printing

Grit Blasting and Vibratory Deburring

Ultrasonic Cleaning

TIG Welding

Assembly and Heli-Coil Installation

Part Marking

Custom Packaging